Shop Air Compressor

After many years the old air compressor bit the bullet. It was time to do a major over haul.

The first thing was to create a compressor. A trick my ol'man taught me is that an old A/C compressor from an old plymouth car should work. Successfully connected to an electric motor that had been collecting dust for years.

The wife reminded me, I had planned ahead when we built the shop I had wired in a plug on the Mezzanine for future expansion of a compressor. It took 20 years but it still paid off in the end.

With the compressor in its new location on the mezz I didn't want it to be too noisy and rattle the stuff off the walls in the wife's tack room located below, so inspired by that crafty genius Wile E coyote, I installed the ACME spring mounting system.

It is surprisingly effective, the dust isn't sifting down through the floor boards onto the tack, happy wife. Even better the new noise level in the shop with the compressor running is 72Db!!

I re used the old air tank as a reservior.

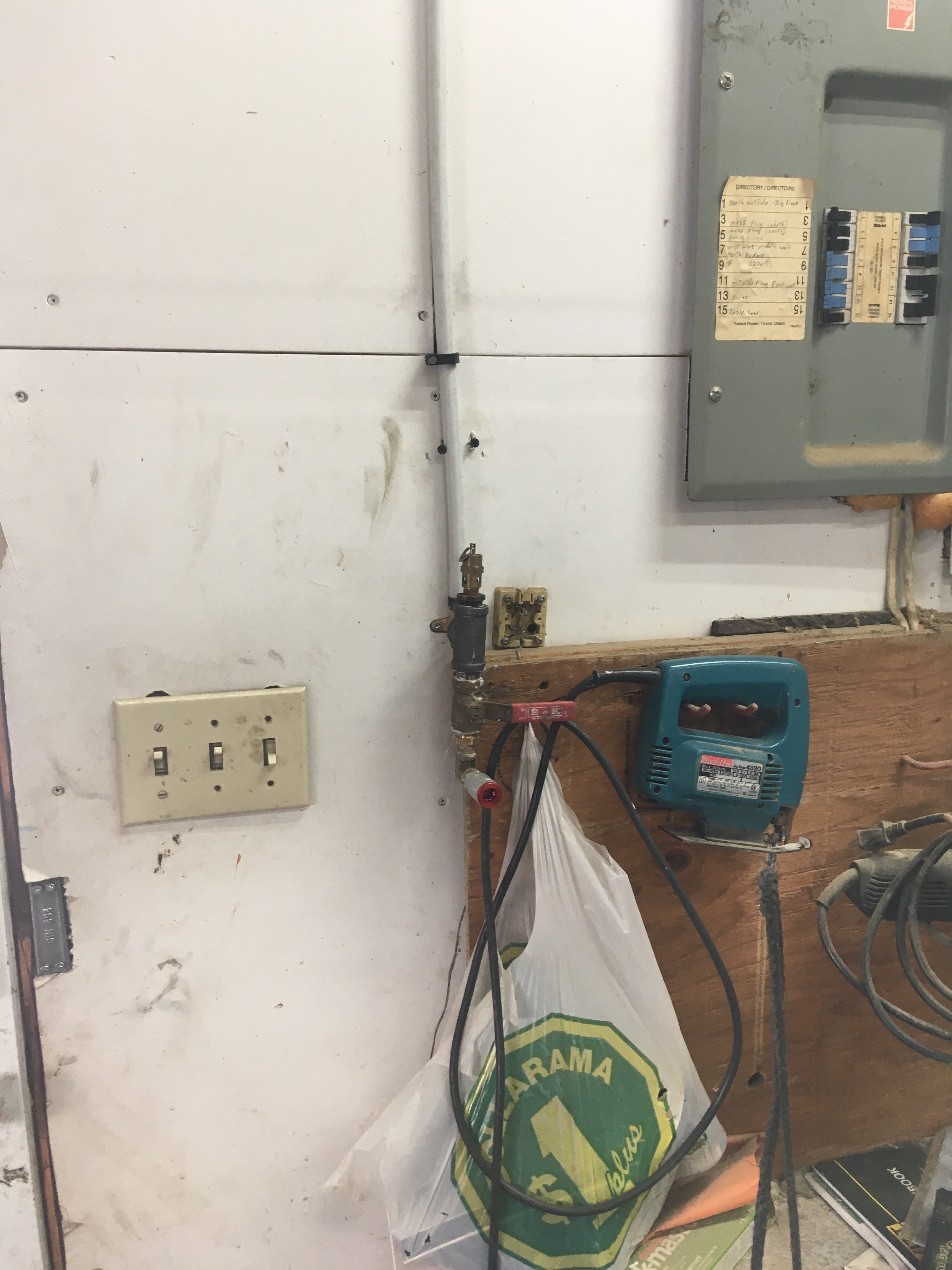

A switch was then wired in to turn the compressor on and off. A light was also installed to assist with remembering to turn the thing off...at least once in a while....the old one had a habit of kicking in on a lovely summer evening when the doors are open interrupting good conversations or a nap, heaven forbid

The image of rolling out 150 ft of airhose to work on something out in the yard got me thinking. Perhaps there has to be a better way? Since I was already getting carried away with this small rebuild I did some research on PEX and it turns out that it is rated for 160PSI. I was OK with that as I am only running 120PSI.

I have fittings everywhere, even at the wood bench for the wife, and only need less than 50ft of hose, most of the time.

Home

Home